Shafts and bearings

Building a small gear train with a good efficiency is not so easy.

One need adequate components and tools.We give here several hints

and DIDEL provides the components. See our price-list

if you are not coming from there.

|

|

|

Loose gears

|

Intermediate gears may be loose on their axis. Play is 0,02mm minimum

and with POM gears, no lubrification is required. If the gear has

a 0.78 mm hole, a steel axis of 0.75-0.76mm or a rivet of 0.76 mm

in diameter is adequate. Rivets are an easy solution in many cases,

because they maintain the gear in place. The carter must be precisely

drilled (0.72 to 0.75 in soft plastic) so the rivet will fit hard,

but not too hard in its hole. It is recommended to taper the rivet

to facilitate its insertion, and avoid that the sharp rivet edge

will enlarge the hole, specially with plastics.

|

|

|

Axis with a carter

|

Axes are good and easy if the gear is maintained at both ends by

an adequate carter. The carter holes are only slightly smaller than

the axis, so the axis can be removed easily. If any play, a drop

of glue can be used to maintain the axis in place.

If the gear overhangs, one can stop the gear with a Quicklock washer

(0.8 mm axis) or, if there is no axial force, a piece of plastic

tube taken from the appropriate electric wire.

|

|

|

Elastic circle

|

|

| For axis of 1.5 mm and larger, on can use elastic circles for smooth

axis, that need a special plyer for insertion. If the axis has to

carry a wheel, a simple solution is to press-fit the wheel on the

last gear. If the wheel has been molded over a gear, the torque can

be enormous. |

|

|

|

Tight gears

|

Tight gears on a small diameter axis cannot transmit an important

torque. POM gears cannot be glued, and the pression of the gear

to the axis is low compared to metal to metal. Inceasing the difference

in diameter to increase the pression may just result in a deformation

of the gear.

For getting a better torque, one should drill a large hole in the

gear, insert a brass sleeve (bore in gear 0.02 to 0.03 mm smaller

than the brass tube), that is press-fitted through the axis (bore

in brass 0.02mm smaller).

|

|

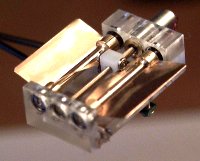

Brass bearings

|

|

| Brass bearings are cheap and easy to implement. They

are press-fitted in the carter, with a 0.02 to 0.05 mm compression

(the bearing will not deform even with high insertion force). Their

precise inside diameter match with steel axis with a minimum play.

Watchmaker oil is recommended: the form of the bearing is designed

to keep the drop of oil in place. |

|

Ball bearings

|

Miniature ball bearings are expensive. They have to

be used when the radial effort is important. For ultra-light planes,

they have the advantage to permit a carbon rod axis. |

|

|

| You like miniature ball bearings? André

Guignard built at

the EPFL in 1998 a nice demonstrator for RMB. The butterfly wing

mechanism uses eight 3mm bearings, plus the two ones inside the 3

mm smoovy motor. If you want to see how it works, there is a beautifull

7 Meg video in MPG format. |

|

|

|